Clothing Repair and Decor with Iron on Patches Workshops in Banbury

A fun and creative workshop where you’ll learn how to repair and decorate your Jeans, Jackets and more using iron-on patches After hearing quite a

You’ve spent a fortune on new uniforms and the kids have gone back to class. Now it’s a waiting game to see which item will be the first to succumb to the rough and tumble of school life. There’s no need to get the unform blues though; our fabric repair patch tips will help you prevent damage in the first place, and have tired schoolwear looking good as new in no time. If you’ve landed here on a quest to discover how to make iron-on patches stay put without coming loose, skip ahead and read Tip 10 first!

Hi, it’s Barbara Gadd here from Vintage-Patch, a UK small business specialising in upcycling supplies and vintage clothing based near Banbury in Oxfordshire. There’s nothing I love more than preventing clothes from ending up in landfill and as it’s the start of a new school year, what better time to put together a list of handy hints that will save you time and money in keeping school uniforms in circulation.

For my ten tips, I’ve listed a few simple repairs and suggestions using a combination of our own School Uniform Mending Kits, sets of Plain Elbow Knee Patches and by making some DIY mending fabric from worn out items of uniform using our Iron on Adhesive Sheets. I talk about Vintage-Patch products as that’s what I’m used to working with and I know how the adhesive responds, but the advice is of a general nature so you can use an alternative brand if that’s what you have to hand.

Looking for iron on patches that won’t fall off? Skip to tip number 10 where you will find an effective solution..

Whilst I love visible mending and quirky multicolour patched fabric upcycles, school uniform repairs present a different challenge, because any work should not draw attention to the wearer. Indeed, intentionally visible repairs are unlikely to be encouraged by the school. Kids may not want to stand out from the crowd in a school setting, so always ask their opinion, and if they favour an external repair such as a pair of elbow patches on their blazer or jumper, consult the school to check this would be permitted. For this reason, most of the repairs that follow are of the ‘invisible’ or at least more discreet kind.

If you have some items of uniform that are too damaged to wear, hang on to a few pieces as you can repurpose the material as iron-on mending fabric. The great thing about this, apart from it being super eco-friendly, is that fabric matching should be easier. It’s a simple matter to iron on Vintage-Patch Adhesive Sheets to the back of pieces of this material (so long as it can be ironed at medium to hot temperatures ) and cut to whatever patch shape you need from it. Worn out school uniform can also be a useful source of upcycling supplies such as replacement buttons, zips and even pocket inners and replacement cuffs.

School trouser knees are subject to plenty of wear and tear so when you buy a new pair, take a few minutes to strengthen the fabric in the knee area with an iron on patch on the inside of the garment. A medium to large cotton square or rectangle applied inside the leg at knee height (measure and mark this when the trousers are on the wearer) can reinforce the fabric and reduce the chance of rips. Using cotton rather than a heavier fabric adds strength but is relatively thin so remains soft and comfortable.

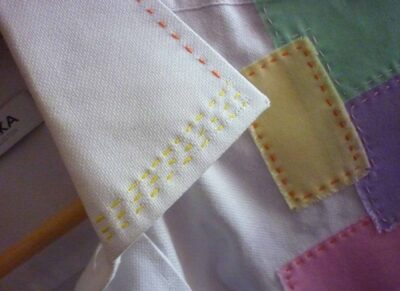

Once applied acccording to pack instructions, using a thread that matches the garment as closely as possible, sew small running stitches along the vertical edges of the patch, or all round it. if done discreetly, your repair shouldn’t be visible on the outside of the trousers, but the stitching will stop patches coming loose over time. Ready made patches such as Vintage patch cotton elbow/knee or uniform repair patches are available in a range of commonly used school uniform colours as pictured above. When repairing from the inside of a garment, the patch colour doesn’t need to match exactly as it won’t be visible from the front. However, if you need to repair with a patch on the outside of knees or elsewhere, using matching fabric from an old piece of uniform can work very well if you can’t find a pre-made knee patch of the shade you need.

For rips in trouser knees, the process is pretty much the same as preventative patching detailed aboove, with a couple of tweaks.

Turn the damaged trousers inside out and iron the area so that the edges of the tear meet as exactly as possible ensuring there are no puckers. Remove the backing from the knee patch and place it glue side down into position over the top, spacing it as equally as possible over the ripped area and taking care not to move the garment fabric underneath. Iron carefully over the top of the patch following pack instructions for the patch you are using.

Now the important bit – don’t skimp on the sewing! Follow up with a line of running stitch sewn all round the edge of the patch, or at the very least down each vertical side of the patch in a closely matching thread colour to the garment.. Turn the trousers to the right side and clip away any long threads from the front of the actual tear and if there are any loose fabric flaps, iron them down and then make a few small running stitches over them to secure. Once the garment is ironed from the top side, the stitching should barely show and will ensure your patch stays in place permanently through washing, tumble drying and the antics of the playground.

If there is a larger hole and the edges don’t meet the area will need patching from both back and front – in effect making a sandwich of patch with glue side down towards the trouser fabric, and then the second patch glue side up towards the trouser fabric.

Ironing over your patches ocasionally after laundering can help recondition the adhesive bond and re-stick any loose edges, though for the longest lasting most durable results in heavy duty garments, we always recommending a combination of adhesive and stitching.

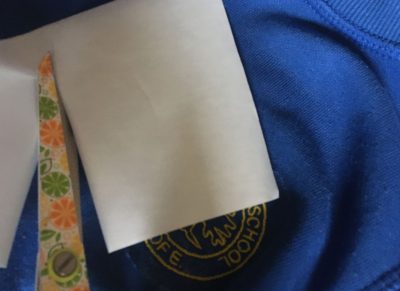

This sweatshirt had a logo from the previous school which needed covering. The new school doesn’t require logos and the owner had an old sweatshirt too worn out to wear, so it was child’s play (forgive the pun) to harvest some matching fabric from that one and create an iron on circular patch. As you see, any circular object of appropriate size can be used as a template for the patch.

Talking of logos, if your school has sew on badges or emblems to apply to the front pocket of blazers or elsewhere, these are really brilliant for reducing uniform costs and should be encouraged. They can be a little tricky to keep in place while stitching so if yours is not already ‘iron on’, applying some adhesive sheet to the back of it and ironing into place can help keep the badge in position while any additional sewing around the edge is carried out. That way, you’ll be less likely to inadvertently sew the pocket shut whilst carrying out the job. And yes, I have made that last mistake and it’s easily done!

Skirt and trouser hems often come loose, and adhesive sheet can be cut up to create hemming strips slightly narrower than the skirt turnup. Apply a strip of adhesive sheet glue side down to the inside (short edge) of the hem and iron into position. Allow to cool, then peel off the backing paper, turn the hem up again and smooth it against the skirt fabric so there are no puckers. Iron into position from the back and front and allow to cool, and voila, your repair is complete. *If working with a pleated skirt you’ll need to ensure you apply the adhesive to the ironed flat fabric and then re-iron the bottom of the pleat folds.

The pictures below show elbow patches applied to the outside of the garment, but if you want to reinforce from the inside,simply turn the garment inside out before proceeding.

Most school knitwear is synthetic these days or has been replaced by sweatshirts, so it takes somewhat longer for elbows to wwear through, but it’s still worth applying a cotton oval or rectangle iron on elbow patch to the inside of knitted jumper and cardigan sleeves to strengthen and reinforce them whilst remaining unobtrusive. Once a hole has occured, the repair is easier if the elbow area is patched from the outside assuming this is acceptable to your child and the school.

It is a help to lightly stitch large holes closed before applying the patch to the top of the garment to stop adhesive flow through the hole. Patching from inside is not possible for blazers unless the sleeve lining is removed, which is a little more complicated than the scope of this article allows, so I recommend asking the school if an outer elbow patch would be permissible.

The white patch in our repair packs is ideal for invisible repairs to the inside of light fabrics such as gingham school dresses, white blouses or polo shirts and cotton fibre based sportswear. Simply cut to size, and follow the directions for the repairs above. Stubborn stains in white shirts that won’t come out by other means can sometimes be hidden by a small piece of iron on patch over the top, so long as it is not too noticeable.

if you’ve run out of nametapes, here’s an easy hack. Use an iron on cotton patch in white and cut it into an appropriate size strip. Write the name onto the strip with a fabric marker pen, peel off the strip’s backing and iron on to the garment.

Last but definitely not least, invest a few minutes in giving your patches extra stability by hand-sewing a line of running stitch around the edge as pictured below. This will make your repair much more durable and able to withstand heavy duty wear and washing that school clothing receives.

So many people get hung up on the concept that iron-on patches should stick and stay in all situations, and they often do if applied under optimum factory conditions, but the reality is that in a domestic setting, garment fabrics, iron temperatures, pressing time and many other variables come in to play which may result in adhesives coming loose over time – however strong they are.

Instead, we should see the three real advantages to using an iron-on product:

1. the patch can be positioned and will stay in place without moving while you secure it in place with stitches

2. the patch will reinforce and strengthen the fabric it is applied to – useful for worn areas that may have thinned.

3. the patch edges are less likely to fray than fabric alone.

“Oh, but I can’t sew…..”

You don’t need to be a seamstress to sew a single line of running stitch. It takes about the same amount of ability as making a frothy coffee or putting air in your car tyres – do it once and it becomes a life skill. All you need is a needle and thread an a smidge of patience, which I promise will be amply rewarded.

Happy Patching!

For more pictorial how to guides on all types of patching plus details of our free ebook ‘Step by Step to Success with Iron on Patches’ click here to visit our Tutorials page.

Get a heads up when our next post is published by signing up to our email list for clothing repair tips, upcycled fashion ideas and exclusive promotions.

A fun and creative workshop where you’ll learn how to repair and decorate your Jeans, Jackets and more using iron-on patches After hearing quite a

Quick and effective ways to keep school clothing in tip top condition throughout the academic year You’ve spent a fortune on new uniforms and the

Step by step instructions on how update an old shirt with iron on patches in Spring pastel shades for the perfect Mother’s Day gift. Simple

Step by step instructions on how to make an orange pumpkin face motif from an iron on patch to decorate a top for Halloween.

Choosing the best colour for iron on elbow or knee patches to add to a piece of clothing can be as simple or as complicated

10th – 17th July 2021 (weather permitting) After so many months of putting all planned events on hold due to the pandemic, I’m very excited

VINTAGE-PATCH

Oxfordshire, United Kingdom

E: [email protected]

Upcycled, vintage and secondhand style for your sustainable wardrobe.